The making of – Bless Me Child For I Have Sinned

Crown Molding

I hand-carved the word, IGNOSCE, which is Latin for FORGIVE ME, in this piece of crown molding and covered it in aluminum sheeting. It is a prototype for the engraving which is on the front of the confessional, "IGNOSCE MIHI INFANS QUIA PECCAVI" which means "BLESS ME CHILD FOR I HAVE SINNED"

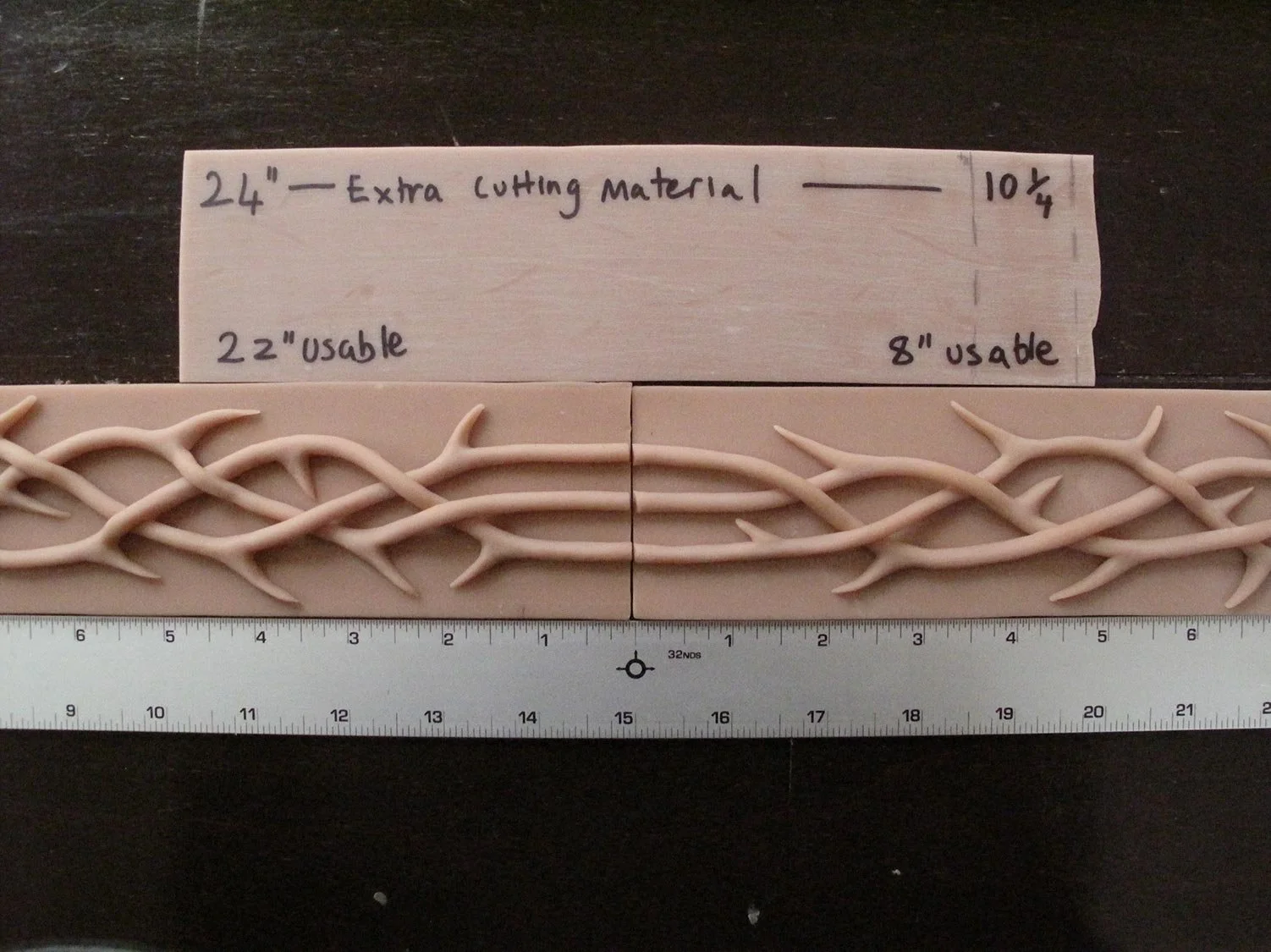

A very important realization occurred to me in April 2011. It was so obvious, but I was trying to use the thorn motif on the hinges when the perfect place for them was the CROWN molding! These are thorns I sculpted on April 25, 2011.

Once I decided to create a thorn design around the crown molding,

I started making prototypes. On top is a thorn design drawn onto aluminum

sheeting in slight relief. Below are 3-D thorns sculpted in clay,

baked in the oven and partially covered in aluminum adhesive foil.

I wanted the crown molding and the thorns to be fabricated from a material that

could be nickel-plated. I found a company that could create a 3-D composite thorn

design from digital laser technology. These are my sculpted clay thorns which were

digitally fabricated into a composite material that was then nickel-plated.

Thorn composite

Thorns made out of the composite material affixed to the prototype.

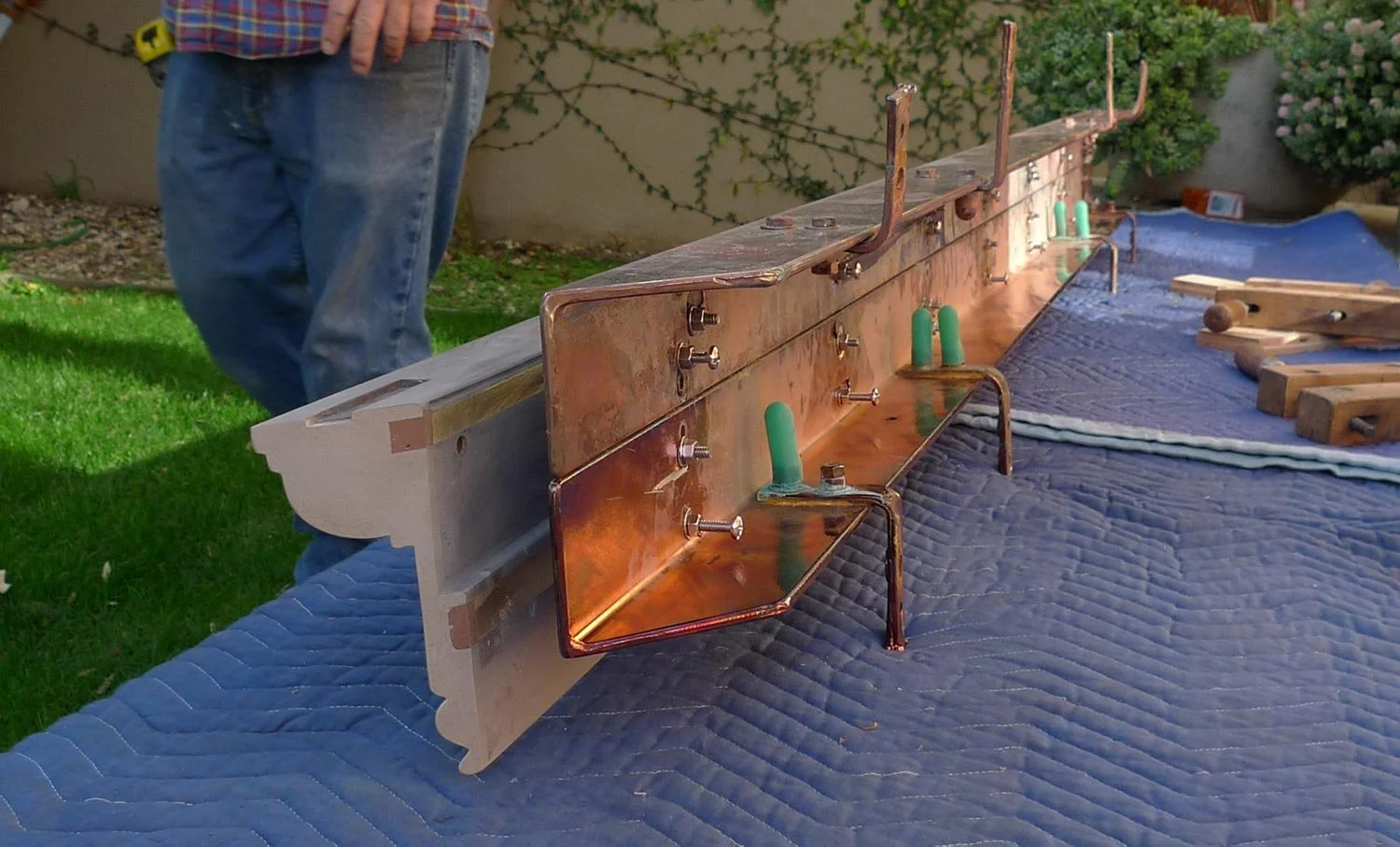

Dec 12, 2012. The crown molding was carved out of a heavy composite material. To keep it supported we had to have brass rods embedded which helped stabilize it during the plating process. There was only one plating company in Southern California that had plating baths big enough to accommodate the length of the crown molding - Quaker Plating. This is the steel armature that was constructed to attach to the molding, which enabled it to be lowered into the plating bath and then retrieved safely after the plating process was completed.

These are the thorns that were processed through the copper substrate layer. They had to be heavily sanded as the copper layer adhered too thickly on the surface and the moldings had to be sanded back to their original size. They are in the back of the truck going back to Quaker Plating to be nickel-plated.

Part of this section has the primer and the adhesive size is on top of the primer. The size has a time window once you apply it. You can't put the gold leaf on immediately or it will not stick properly. There is a perfect time when the gold leaf will stick to it flawlessly. This was the first time I ever gold-leafed anything so I was nervous about the process. It ended up being an exciting experience seeing the gold applying like butter!

The crown molding successfully nickel-plated and ready for installation.

This is a front section of the crown molding with the thorns primed to seal the surface before the adhesive size is applied.

This is the front crown molding ready to be gold-leafed. It was very exciting to get to this moment to apply the gold leaf and see it transform the thorns into glistening jewels.